ABOUT HAZER GROUP

Hazer Group was founded in 2010 to commercialise technology originally developed at the University of Western Australia. The Company listed on the ASX in December 2015.

Prior to listing, more than eight years was spent developing the underlying HAZER® Process. The Process, which uses natural gas and unprocessed iron ore, creates a low cost and low emissions “clean” hydrogen. The clean hydrogen produced is considered to be a key fuel in the transition to a low carbon economy.

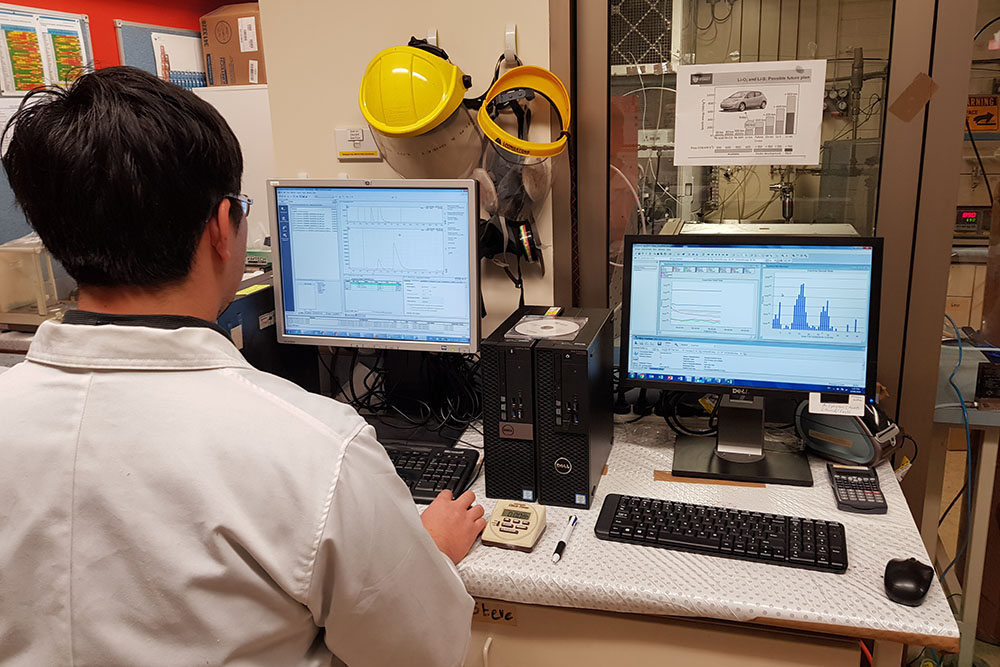

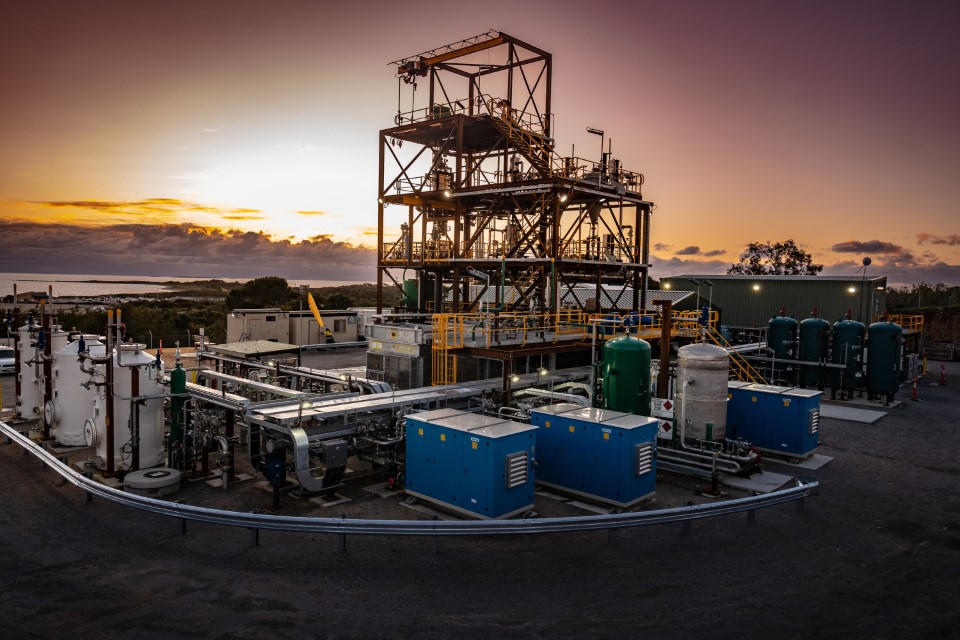

In early 2016, Hazer developed a research partnership with the University of Sydney, and established its core development operations within the School of Chemical and Biomolecular Engineering at the University. The company has now completed construction of a Commercial Demonstration Plant (CDP), situated in Perth, Western Australia.

HAZER’S VISION

Provide a unique climate technology to transform industry and contribute to a sustainable future for the next generation.

HAZER’S VALUES

For Tomorrow

All roads lead to the next generation

All Grit

Determined & resilient, we get it done

People Power

We value each other, our people are our secret weapon

Limitless

We love going beyond our limits

Want to know more?

THE HAZER PROCESS

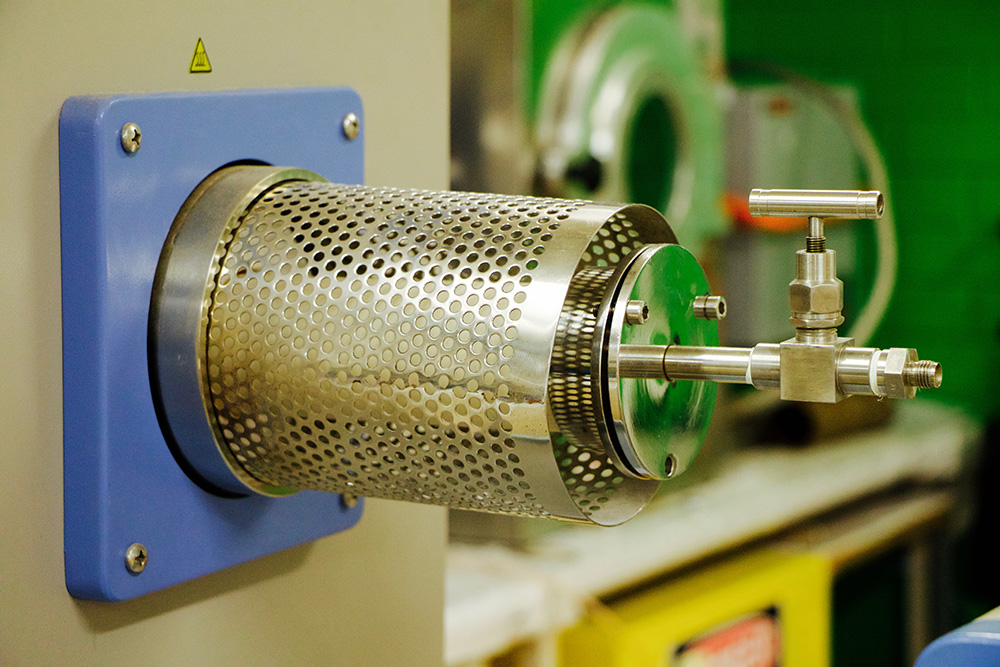

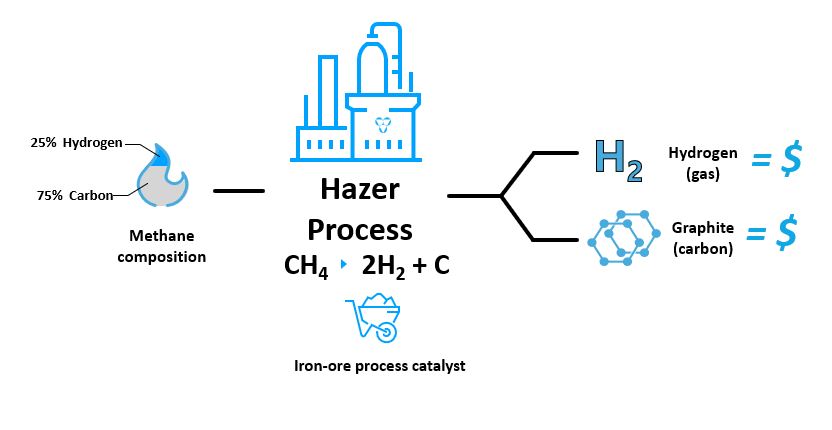

The HAZER® Process enables the effective conversion of natural gas, and similar feedstocks, into hydrogen and high quality graphite, using iron ore as a process catalyst. The aim of the HAZER® Process will be to achieve savings for the hydrogen producer, as well as providing ‘clean’ hydrogen with significant lower carbon dioxide emissions, enabling such hydrogen to be used in a range of developing ‘clean energy’ applications, as well as in large existing chemical processing industries.

OUR MARKETS

Industrial Hydrogen

Cheaper and cleaner alternative

The HAZER® Process produces ‘clean’ and economically competitive hydrogen with at least 50% emission reduction anticipated over alternative fossil fuel based hydrogen production like Steam Methane Reforming (SMR).

With a global market worth over US$100 billion, hydrogen is widely used as an industrial chemical – primarily within the petroleum industry and for the production of ammonia. Traditionally the high cost of production and the large CO2 emissions that are created when producing hydrogen has limited the development of the hydrogen-based energy market.

Industrial Hydrogen

Cheaper and cleaner alternative

The HAZER® Process produces ‘clean’ and economically competitive hydrogen with at least 50% emission reduction anticipated over alternative fossil fuel based hydrogen production like Steam Methane Reforming (SMR).

With a global market worth over US$100 billion, hydrogen is widely used as an industrial chemical – primarily within the petroleum industry and for the production of ammonia. Traditionally the high cost of production and the large CO2 emissions that are created when producing hydrogen has limited the development of the hydrogen-based energy market.

Hydrogen Mobility

Markets emerging for clean energy

The low emissions hydrogen produced by our process offers a pathway to decarbonise transportation.

Hydrogen used as a fuel in Fuel Cell Electric Vehicles can displace liquid fuels used in mobility such as passenger vehicles, buses, trucks and other heavy duty vehicles – including rubbish collection vehicles and long-haul road transport.

Synthetic Graphite

Unique alternative

The HAZER® Process produces high quality, low cost synthetic graphite. Our graphite is highly crystalline and has excellent comparison to high-end commercial forms of graphite used in lithium-ion batteries.

Importantly, there is less environmental damage, as Hazer does not need to excavate mass areas of land like natural graphite extraction and does not require the use of harsh chemicals like petroleum coke used to create current synthetic graphite.

Synthetic Graphite

The Unique Alternative

The HAZER® Process produces high quality, low cost synthetic graphite. Our graphite is highly crystalline and has excellent comparison to high-end commercial forms of graphite used in lithium-ion batteries.

Importantly, there is less environmental damage, as Hazer does not need to excavate mass areas of land like natural graphite extraction and does not require the use harsh chemicals like petroleum coke used to create current synthetic graphite.